The action procedure of various Cold Chamber Die Casting Machines may not be completely consistent according to various requirements, but the process content to be completed, that is, the basic procedure, is the same. The MT400 cold chamber die-casting machine produced by YOMATO MACHINERY is given as an example.

The cycle period of the Cold Chamber Die Casting Machine is calculated at the beginning of closing the door. After closing the mold, the core is inserted before locking the mold, and then the die-closing hydraulic cylinder and the hyperbolic elbow amplification mechanism begin to work, so that the mold is first closed quickly with low pressure. When the moving seat plate and the shaped seat plate are approaching (the position setting and detection are handled accurately by the computer with extremely high precision electronic ruler), the power system of the die-closing mechanism is automatically replaced with low pressure (i.e. test-closing force) and low speed. After confirming that there is no foreign body in the cavity and the inserts are not loose, switch to high pressure to lock the mold, and then pull the core insert after locking the mold. The core-pulling mechanism is provided with two sets of control procedures for selection, the first group is pre-locking insert, after opening mold reset; the second group is after mode-locking termination insert, before opening mold reset.

After confirming that the mold has reached the required locking degree, the soup machine is automatically given to the soup (or artificial soup can be used). Then, the pressure ejection system then pushes the molten metal into the cavity according to the slow pressure ejection (i.e. one-speed pressure ejection), the fast pressure ejection (i.e. two-speed pressure ejection) and the pressurized three-stage pressure ejection motion.

When it is determined that the metal flux in the cavity loses the possibility of reflow from the inlet, according to the cycle time and operation procedure set in the computer, the mechanism of core-pulling insertion is core-pulled and reset, then the system moves slowly and slowly to prevent the mold-pulling from damaging the mold and product. At the same time, the front safety door opens automatically, then the mechanism of core-pulling insertion and the core-poring return position.

The pick-up manipulator is in place, the hydraulic cylinder is pushed out of the workpiece, and the manipulator holds the workpiece back position and carries on the workpiece confirmation (also can be replaced by the manual pick-up workpiece to take the workpiece manipulator). Meanwhile, the punch hammer. After the determination of foreign body in the mold cavity, the sprayer automatically sprays the release (release) agent (also can be sprayed manually) into the mold cavity, at the same time, the punch lubrication device is sprayed with lubricating oil to the punch, and the machine door is automatically (or manually) closed by the pneumatic device, and after confirmation, it enters the next working cycle.

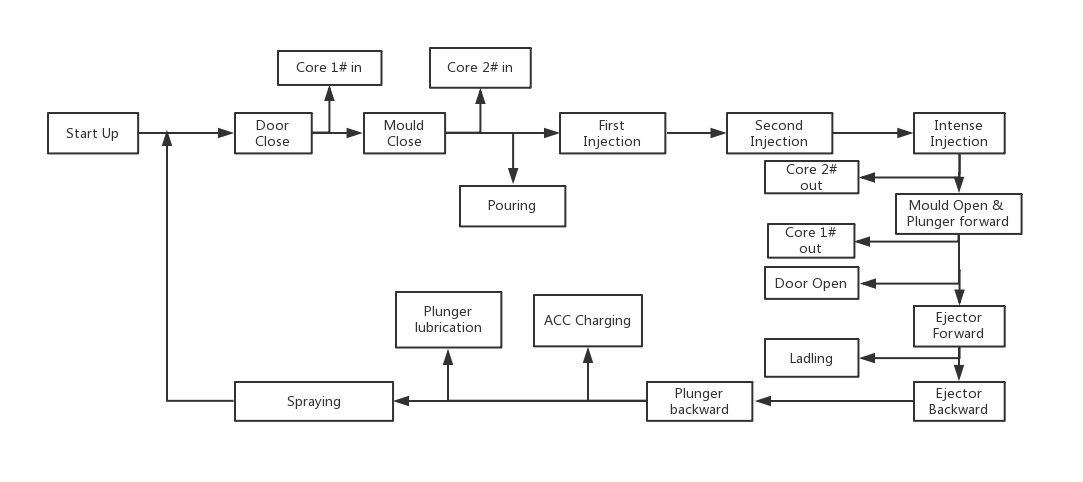

the above process can be drawn in chronological order into a die casting working cycle diagram, as shown in figure 1-11.

Figure 1-11 MT400 Die casting working cycle

Figure 1-11 MT400 Die casting working cycle

.jpg)

Contact: Sean Jiang

Phone: +86-13777149766

E-mail: [email protected]

Whatsapp:8613777149766

Add: No.6,Wenjing Road,Jintan Economic Development Zone,Changzhou,Jiangsu,China

We chat