Application of Magnesium Alloy Die Casting Machine

Keywords: Applications of Magnesium Alloy, Production Process, Benefits of Magnesium Alloy Products

Introduction:

Magnesium alloy is a lightweight and highly versatile material that has gained significant attention in various industries. The use of magnesium alloy in different products has increased due to its excellent properties such as high strength-to-weight ratio, good corrosion resistance, and high thermal conductivity. This article explores the applications of magnesium alloy, the production process, and the benefits it brings to the manufacturing industry.

Applications of Magnesium Alloy:

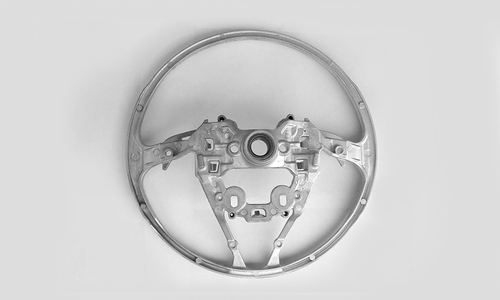

1. Automotive Industry: The automotive industry has been one of the major adopters of magnesium alloy due to its lightweight properties. Magnesium alloy components are used in various parts of vehicles, including engine blocks, transmission cases, steering wheels, and interior trim. The use of magnesium alloy in automobiles not only reduces the weight of the vehicle but also improves fuel efficiency and reduces emissions.

2. Aerospace Industry: Magnesium alloy is also widely used in the aerospace industry. It is used in the construction of aircraft components such as aircraft frames, landing gears, and engine parts. The lightweight nature of magnesium alloy contributes to fuel efficiency and allows for increased payload capacity.

3. Electronics Industry: Magnesium alloy is increasingly used in the electronics industry due to its excellent electromagnetic shielding properties. It is used in the production of mobile phone casings, laptops, and tablets. The use of magnesium alloy in electronic devices not only provides durability but also helps dissipate heat generated by the components.

4. Sports Equipment: Magnesium alloy is used in the manufacturing of sports equipment such as golf clubs, tennis rackets, and bicycles. Its lightweight nature contributes to improved performance and maneuverability.

Production Process:

The production of magnesium alloy components involves a process known as die casting. Die casting is a manufacturing process where molten metal is injected into a mold cavity under high pressure. The mold is then cooled, and the solidified part is ejected from the mold. This process allows for the production of complex shapes with high precision.

The die casting process for magnesium alloy involves the following steps:

1. Melting: Magnesium alloy is melted in a furnace at a controlled temperature.

2. Injection: The molten magnesium alloy is injected into the die casting machine under high pressure. The machine consists of two main parts, the injection unit, and the die. The injection unit is responsible for melting and injecting the molten metal into the die.

3. Cooling: After injection, the mold is cooled to solidify the magnesium alloy.

4. Ejection: Once the part is solidified, it is ejected from the mold.

Benefits of Magnesium Alloy Products:

1. Lightweight: Magnesium alloy is one of the lightest structural materials available, making it ideal for applications where weight reduction is crucial.

2. High Strength-to-Weight Ratio: Despite its lightweight nature, magnesium alloy offers excellent strength, allowing for the production of strong and durable components.

3. Good Corrosion Resistance: Magnesium alloy exhibits good corrosion resistance, making it suitable for use in harsh environments.

4. High Thermal Conductivity: Magnesium alloy has excellent thermal conductivity, allowing for efficient heat dissipation.

5. Recyclability: Magnesium alloy is highly recyclable, contributing to environmental sustainability.

Conclusion:

The applications of magnesium alloy are diverse and rapidly expanding. Its lightweight nature, high strength-to-weight ratio, and other excellent properties make it an ideal choice for various industries such as automotive, aerospace, electronics, and sports equipment. The die casting process enables the production of complex magnesium alloy components with high precision. The benefits of using magnesium alloy products include weight reduction, improved performance, and environmental sustainability. With continuous research and development, the applications of magnesium alloy are expected to grow further in the future.

.jpg)

Contact: Sean Jiang

Phone: +86-13777149766

E-mail: [email protected]

Whatsapp:8613777149766

Add: No.6,Wenjing Road,Jintan Economic Development Zone,Changzhou,Jiangsu,China

We chat