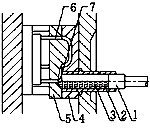

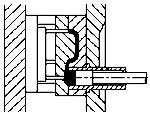

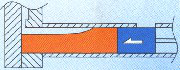

As shown in figure 1-2, after die-casting die closing, molten metal 3 is poured into the press chamber 2, the pressure injection head 1 is pushed forward, and the molten metal is pressed into the mold chamber 6 through the sprue 7 to cool and solidify. When the mold is opened, the pressure injection punch extends forward to push out the surplus material, the ejection hydraulic cylinder thimble pushes out the casting, the punch is reset, and a die casting cycle is completed.

Fig .1-2 Schematic diagram of die casting process in cold chamber

1-- Plunger head 2-- Sleeve 3-- liquid metal 4-- fixed mould 5-- movable mould 6-- mould cavity 7-- sprue 8-- movable mould platen 9-- ejector 10-- residual material 11-- fixed mould platen

The pressing motion process of the pressure injection can be divided into two or three stages.

The first stage: pressing the plunger head to push the metal liquid at a slow speed, so that the metal liquid fills the front end of the sleeve and heaps the inner gate front. This stage can make the sleeve air escape more fully and prevent the metal liquid from spilling out from the gate.

The second stage: the pressure injection head moves quickly, makes the metal liquid fill to the cavity quickly through the sprue.

The third stage: the final pressure stage, the pressure injection head continues to move, compacts the metal, the punch speed gradually drops to zero. This phase must be implemented when the pressurization mechanism is available in the machine pressurization system.

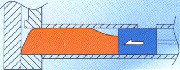

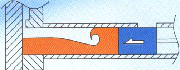

In the process of die-casting filling, the speed of the die-injection head advancing directly affects the quality of the casting. as shown in figure 1-3, when the motion speed of the die-injection head in the first stage is too low or too high, it is not good for the casting quality. In order to eliminate the gas storage problem of die casting effectively, the pressure injection head can adopt uniform acceleration motion at this stage, that is, the pressure injection speed increases gradually from zero to a suitable value, and the metal liquid will not splash out from the gate under the push of the pressure injection head, and can form a smooth wave amplitude to discharge the air.

(a) (b) (c)

Figure 1-3, Schematic illustration of the first stage compression motion

a)The speed is too low, the air is trapped in the tail

b)The speed is too high, the air is trapped in the spray

c)At the critical pressure velocity, a slip wave can be formed to drain the air

.jpg)

Contact: Sean Jiang

Phone: +86-13777149766

E-mail: sales@yomato-machinery.com

Whatsapp:8613777149766

Add: No.6,Wenjing Road,Jintan Economic Development Zone,Changzhou,Jiangsu,China

We chat