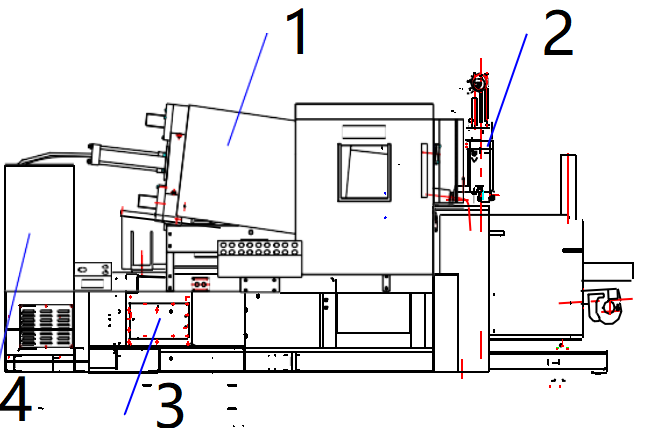

The hot chamber die-casting machine is mainly composed of four parts: clamping unit, injection unit,hydraulic transmission system and the electrical control system, which are shown in Fig .1-9.

Hot chamber die casting machine

1-Clamping unit 2-Injection Unit 3-Hydraulic transmission system 4-Electrical control system

The Clamping unit is mainly used to realize the action of closing, opening and locking the mould and ejection.

The injection unit is a device for injecting molten alloy liquid into the mould cavity. It is mainly composed of pressure chamber, plunger head, injection hydraulic cylinder, nozzle and other components.

Hydraulic transmission system is a system that transmits power through various hydraulic components and circuits, thus realizing various action procedures. It is mainly composed of hydraulic pump, die-locking hydraulic cylinder, thimble hydraulic cylinder, buckle nozzle hydraulic cylinder, pressure jet hydraulic cylinder, various control valves, accumulators, tank cooler, hydraulic oil and so on.

Electrical control system is to ensure that the machine works according to the predetermined pressure, speed, temperature and time, it is mainly composed of motor and various electrical components, instruments, electrical wiring.

(1) Clamping unit

The structure, function and working principle of die-shaping device of hot chamber die-casting machine are the same as those of cold chamber die-casting machine.

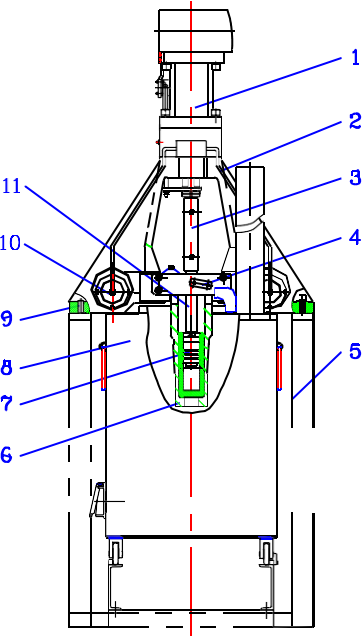

(2) Injection unit

The structural performance of the injection unit plays a decisive role in the pressure ejection force, the pressure ejection speed and the quality of the die casting. As shown in Fig .1-10, the injection unit diagram of the die-casting machine in the injection chamber is equipped with the injection hydraulic cylinder assembly and the buckle nozzle hydraulic cylinder assembly and the hydraulic accumulator on the injection stand. The injection piston rod moves upward (or downward) at a certain speed under the action of the hydraulic oil, thus driving the injection hammer head to move in the injection chamber. The speed of pressure ejection is divided into two sections, the second stage is supplemented by the hydraulic pressure of the hydraulic accumulator to achieve rapid pressure ejection, and the speed of pressure ejection can be adjusted by the speed regulating handwheel. The function of the hydraulic cylinder assembly of the buckle is to drive the motion of the die-closing cylinder frame through the movement of the piston rod of the buckle, so that the die inlet installed on the shaped seat plate leaves the nozzle head or matches the nozzle head.

Fig .1-10 injection unit of hot chamber die casting machine

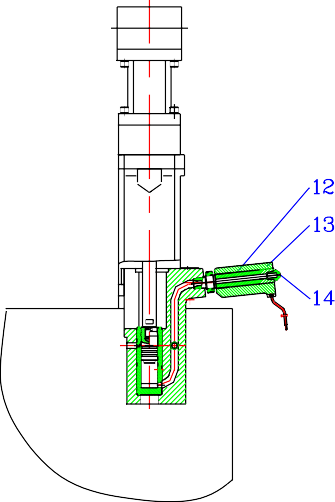

1- Hydraulic cylinder 2-Injection Stand 3-Injection Connector 4- Stuffler Baffle 5- Stand-up Component 6- Pots 7- Hammer head

8- Furnace 9- Vertical Position Pin 10- Buckle Hydraulic Cylinder 11- Injection piston rod 12- Nozzle body 13- Heating ring 14- Nozzle head

Hydraulic accumulator

The structure, function and working principle of the hydraulic accumulator device of the Hot Chamber Die Casting Machine are the same as those of the Cold Chamber Die Casting Machine.

.jpg)

Contact: Sean Jiang

Phone: +86-13777149766

E-mail: [email protected]

Whatsapp:8613777149766

Add: No.6,Wenjing Road,Jintan Economic Development Zone,Changzhou,Jiangsu,China

We chat